Ferrite and Nanocrystalline Product Family

TI-Electronic – Knowledge-based electronic manufacturing

Expertise in Ferrite and Iron Powder Core Production

est.

1992

Decades of expertise

98,6

%

Satisfied customers

Since 1996, TI-Electronic has been a leader in the development and production of ferrite and powdered iron core products. With decades of experience in the industry, we offer a wide range of high-quality core products that are rigorously tested to meet industry standards.

Our partner in the development of cores is the Hungarian Central Physical Research Institute.

Our cores are widely used in various fields, including:

- Industrial electronics

- Broadcasting technology

- Lighting technology

- Automotive industry

Our inductor division manufactures and develops coils, transformers, and filters from these cores based on client needs. Our dedication to quality ensures that each product meets the specific requirements of its intended application.

You can download the detailed catalog of our ferrite and iron powder core products from our website. Additionally, we offer custom production and quality control for product types not listed in our catalog.

Nanocrystalline Material Cores

At TI-Electronic, we are also specialists in the production of cores made from nanocrystalline materials. These materials allow us to produce inductive elements that meet the ever-growing demands of frequency and operating temperature in modern electronics.

Key Features of Nanocrystalline Cores:

- High-frequency performance: Metal-metal type nanocomposites can be used up to 10 MHz, while metal-insulator nanocomposites operate up to GHz range frequencies.

- Versatile permeability: Through specialized heat treatment, the permeability of our nanocrystalline cores can be adjusted between 25,000 and 90,000, allowing for highly customizable applications.

- Wide application range: Our cores are suitable for switch-mode power supplies, current meters, and other electronic systems requiring low permeability and linear magnetization.

Currently, we focus on producing metal-metal nanocomposites, specifically nanocrystalline alloys. These alloys are made by heat-treating amorphous structures, which are produced by rapid cooling. We can produce amorphous tapes in widths between 4 and 20 mm, and larger cores are created by stacking thinner cores together.

Fe-based nanocrystalline material with composition of mostly Fe with Cu,Nb,Si,B, which first by rapid quenching technology to form amorphous ribbon, then by crystalline heat treatment to gain fine grains with nano scale. Through this revolutionary process, we can get superior magnetic properties with high saturation flux density, high initial permeability, low coercivity, low core loss. Nanocrystalline material is an environmental protection, green, low carbon,high efficiency new magnetic material.

Magnetic Properties Comparison: Amorphous and Nanocrystalline VS Traditional Soft Magnetic Materials:

Fe-Si Steel | Mn-Zn Ferrite | 80Ni Permalloy | Cobalt-based Amorphous | Fe-based Amorphous | Fe-based Nanocrystalline | |

Saturation Flux Density Bs(T) | 2.03 | 0.5 | 0.74 | 0.58 | 1.56 | 1.25 |

Coercivity Hc (A/m) | 40 | 8 | 2.4 | 0.4 | 2.4 | 1.2 |

Initial Permeability μi | 1500 | 3000 | 40000 | 100000 | 5000 | 80000 |

Max Permeability μm | 20000 | 6000 | 200000 | 1000000 | 50000 | 400000 |

Electrical Resistivity (μΩ .cm) | 50 | 5×107 | 60 | 140 | 130 | 115 |

Curie Temperature Tc(°C) | 750 | 220 | 450 | 250 | 399 | 570 |

Applications of Amorphous and Nanocrystalline Cores:

Application | Fe-based Amorphous | Co-based Amorphous | Fe-based Nanocrystalline |

EMC, EMI, EMC Common Mode Choke, EMI Filter | √ | ||

Current Transformer | √ | √ | |

High Frequency Transformer | √ | ||

Magnetic Amplifier | √ | √ | |

Network transformer, driver transformer | √ | √ | |

Solar Inverter Reactor | √ | ||

Car Audio output inductor | √ | ||

PFC, PFC choke, Out filter inductor | √ | √ |

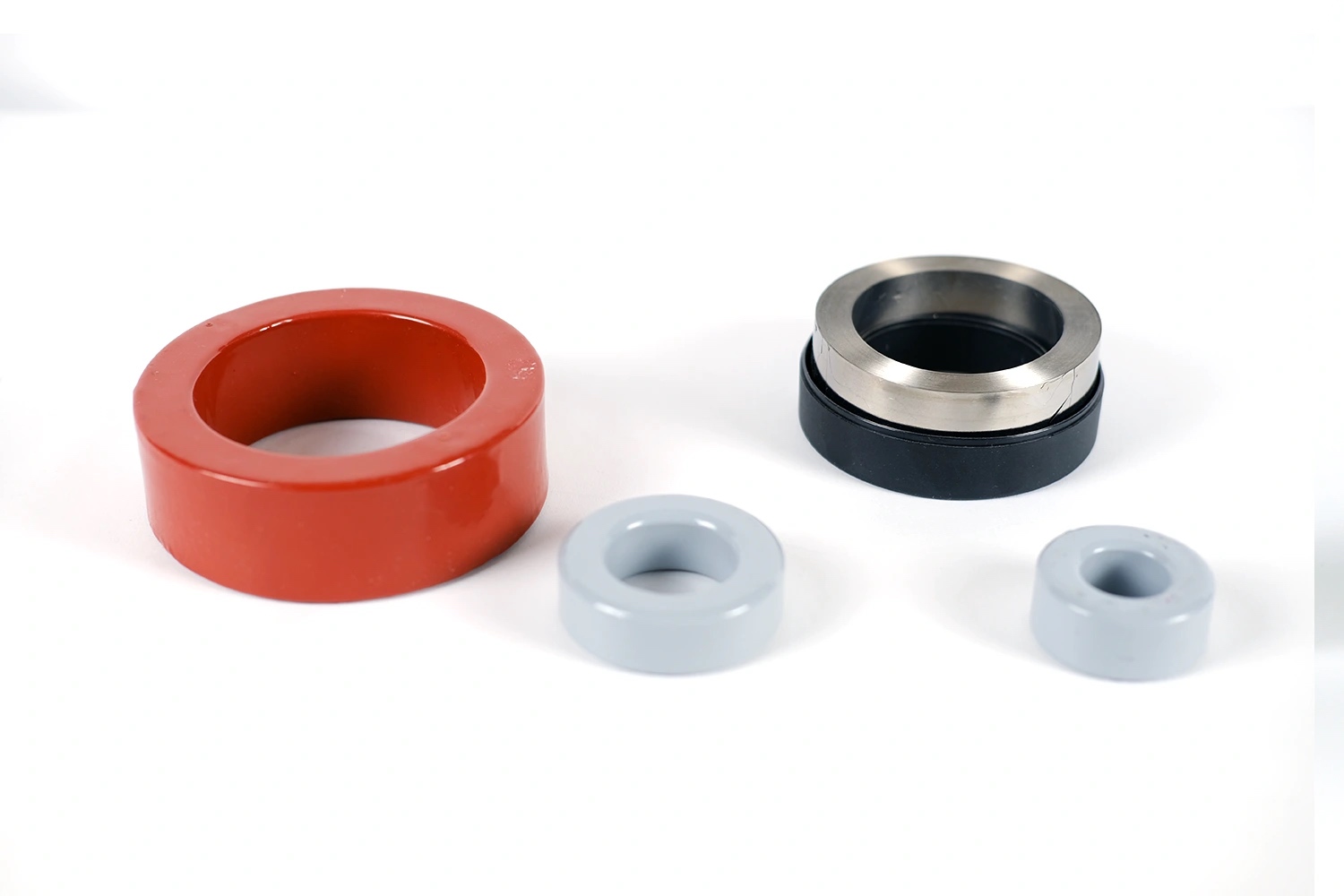

Nanocrystalline Product Family

Nanocrystalline cores for EMC common mode chokes

✅ Overview – Nanocrystalline Cores for EMC Common Mode Chokes

✔️ Ultra-high permeability – wideband noise filtering from 1 kHz to 10 MHz

✔️ High inductance in small size – 2–3× better performance than ferrite

✔️ Lower winding count – reduces copper usage and core losses

✔️ High Curie temperature (560 °C) – stable up to 120 °C continuous use

✔️ Applications:

– EMC filters and common mode chokes

– SMPS, server and computer power supplies

– Solar & wind power inverters

– EV chargers, UPS, VFDs, servo motors

– Laser/X-ray power and industrial electronics

📌 Nanocrystalline cores are the preferred material for high-performance common mode chokes due to their superior EMI suppression, thermal stability, and compact size.

🛠 Custom sizes and epoxy coating options available.

Turn your MOBILE horizontally to see the full table

| Part Nr. | Core dimension (mm) | Case dimension (mm) | Eff. | Mean | AL(μH) | AL(μH) | ||||

od | id | h | OD | ID | H | Ae | Lm | AL | AL | |

TIE-NANO-EMC-986545 | 9.8 | 6.5 | 4.5 | 11.3 | 5 | 6.1 | 0.06 | 2.6 | 25.5 | 6.4 |

TIE-NANO-EMC-120805 | 12 | 8 | 5 | 14.4 | 6.5 | 7.0 | 0.08 | 3.1 | 28.0 | 6.8 |

TIE-NANO-EMC-151005 | 15 | 10 | 4.5 | 17.1 | 8.3 | 7.1 | 0.09 | 3.9 | 27.0 | 6.7 |

TIE-NANO-EMC-161006 | 16 | 10 | 6 | 17.9 | 8.1 | 8.1 | 0.14 | 4.1 | 43.0 | 10.1 |

TIE-NANO-EMC-161008 | 16 | 10 | 8 | 17.8 | 8.4 | 9.9 | 0.19 | 4.1 | 46.1 | 11.5 |

TIE-NANO-EMC-171206 | 17.5 | 12.6 | 6 | 19.2 | 10.9 | 8.1 | 0.11 | 4.7 | 30.0 | 6.9 |

TIE-NANO-EMC-191510 | 19 | 15 | 10 | 21.2 | 13.5 | 12.3 | 0.16 | 5.3 | 36.1 | 8.8 |

TIE-NANO-EMC-201208 | 20 | 12 | 8 | 21.7 | 10.8 | 9.9 | 0.25 | 5.0 | 55.2 | 13.6 |

TIE-NANO-EMC-201210 | 20 | 12 | 10 | 22.6 | 10.5 | 12.5 | 0.31 | 5.0 | 62.4 | 15.6 |

TIE-NANO-EMC-211510 | 21 | 15 | 10 | 23.6 | 12.8 | 12.7 | 0.23 | 5.7 | 41.6 | 10.4 |

TIE-NANO-EMC-252010 | 25 | 20 | 10 | 28 | 17.2 | 13.2 | 0.20 | 7.1 | 28.4 | 7.3 |

TIE-NANO-EMC-251610 | 25 | 16 | 10 | 28 | 14.0 | 13.1 | 0.35 | 6.4 | 67.0 | 15.5 |

TIE-NANO-EMC-261610 | 25.5 | 16 | 10 | 28.4 | 13.9 | 13 | 0.39 | 6.6 | 57.1 | 14.3 |

TIE-NANO-EMC-302010 | 30 | 20 | 10 | 33.2 | 17.8 | 13.3 | 0.39 | 7.9 | 59.3 | 14.0 |

TIE-NANO-EMC-302015 | 30 | 20 | 15 | 33.6 | 17.8 | 17.8 | 0.59 | 7.9 | 88.0 | 20.0 |

TIE-NANO-EMC-322010 | 32 | 20 | 10 | 34.4 | 18.0 | 13.1 | 0.47 | 8.2 | 57.6 | 14.4 |

TIE-NANO-EMC-322015 | 32 | 20 | 15 | 34.6 | 17.9 | 18.2 | 0.70 | 8.2 | 86.4 | 21.6 |

TIE-NANO-EMC-382415 | 37.8 | 24.2 | 15 | 40.8 | 21.6 | 18.3 | 0.80 | 9.7 | 82.1 | 20.5 |

TIE-NANO-EMC-402515 | 40 | 25 | 15 | 43.8 | 21.6 | 18.8 | 0.88 | 10.2 | 99.0 | 23.1 |

TIE-NANO-EMC-402520 | 40 | 25 | 20 | 45 | 21.5 | 24.7 | 1.17 | 10.2 | 115.2 | 28.8 |

TIE-NANO-EMC-403215 | 40 | 32 | 15 | 44.9 | 28.8 | 18.8 | 0.47 | 11.3 | 48.0 | 11.3 |

TIE-NANO-EMC-453015 | 45 | 30 | 15 | 48.3 | 26.4 | 18.2 | 0.88 | 11.8 | 87.6 | 20.0 |

TIE-NANO-EMC-462725 | 46 | 27 | 25 | 48.8 | 24.6 | 27.8 | 1.85 | 11.5 | 162.4 | 40.6 |

TIE-NANO-EMC-503220 | 50 | 32 | 20 | 53.8 | 28.5 | 23.8 | 1.40 | 12.9 | 109.6 | 27.4 |

TIE-NANO-EMC-504020 | 50 | 40 | 20 | 53.6 | 37.1 | 23 | 0.78 | 14.1 | 45.0 | 13.5 |

TIE-NANO-EMC-635025 | 63 | 50 | 25 | 69 | 46 | 29 | 1.27 | 17.7 | 59.0 | 17.5 |

TIE-NANO-EMC-644020 | 64 | 40 | 20 | 68.2 | 37 | 23.5 | 1.87 | 16.3 | 115.2 | 28.8 |

TIE-NANO-EMC-644025 | 64 | 40 | 25 | 67.4 | 37 | 29.2 | 2.34 | 16.3 | 144.0 | 36.0 |

TIE-NANO-EMC-805020 | 80 | 50 | 20 | 83.8 | 46.6 | 25.0 | 2.34 | 20.4 | 94.0 | 28.0 |

TIE-NANO-EMC-805025 | 80 | 50 | 25 | 84.0 | 47.0 | 29.0 | 2.93 | 20.4 | 144.0 | 36.0 |

TIE-NANO-EMC-906020 | 90 | 60 | 20 | 95.4 | 54.7 | 24.7 | 2.34 | 23.6 | 81.0 | 25.1 |

TIE-NANO-EMC-1008020 | 100 | 80 | 20 | 105 | 75 | 25 | 1.56 | 28.3 | 55.5 | 13.9 |

TIE-NANO-EMC-1027625 | 102 | 76 | 25 | 108.1 | 70.0 | 30.3 | 2.54 | 27.9 | 91.1 | 22.8 |

TIE-NANO-EMC-108025 | 110 | 80 | 25 | 116.6 | 73.8 | 31.4 | 2.93 | 29.8 | 98.5 | 24.6 |

TIE-NANO-EMC-1309030 | 130 | 90 | 30 | 135.3 | 84.9 | 36.5 | 4.68 | 34.5 | 136.1 | 34.0 |

TIE-NANO-EMC-14010025 | 140 | 100 | 25 | 145 | 95 | 30 | 3.90 | 37.7 | 91.0 | 26.0 |

TIE-NANO-EMC-16013025 | 160 | 130 | 25 | 165 | 125 | 30 | 2.93 | 45.5 | 56.5 | 16.1 |

TIE-NANO-EMC-17012025 | 170 | 120 | 25 | 175 | 115 | 30 | 4.88 | 45.5 | 94.1 | 26.9 |

TIE-NANO-EMC-20016030 | 200 | 160 | 30 | 207 | 153 | 37 | 4.50 | 56.5 | 72.8 | 20.8 |

The AL value tolerance of the products is regulated in the quality agreement concluded with the customer.

Nanocrystalline Current Transformer Cores

✅ Overview – Nanocrystalline Current Transformer Cores

✔️ High-permeability nanocrystalline alloy for precision measurement

✔️ High accuracy – suitable for 0.1 / 0.2 / 0.2S / 0.5S class CTs

✔️ Stable performance from -40 °C to +130 °C

✔️ Compact core sizes for space-constrained applications

✔️ Low excitation current and core loss – improved sensitivity

✔️ Cost-effective vs. permalloy – ~30% lower production cost

✔️ Wide linearity range – performs well under high fault currents

✔️ Applications:

– Precision current transformers for energy meters

– PDU monitoring and smart grid systems

– Combined CT modules and compact instruments

Turn your MOBILE horizontally to see the full table

Part Nr. | Core dimension (mm) | Case dimension (mm) | Eff. | Mean | Exciting | Excitation | ||||

od | id | h | OD | ID | H | Ae | Lm | N1=1 | N2=1 | |

TIE-NANO-CT-139.505 | 13 | 9.5 | 5 | 14.5 | 8.33 | 6.1 | 0.068 | 3.53 | 10 | 0.1 |

TIE-NANO-CT-13.29.610 | 13.2 | 9.6 | 10 | 15.1 | 8.5 | 12.0 | 0.14 | 3.58 | 10 | 0.2 |

TIE-NANO-CT-151005 | 15 | 10 | 5 | 16.6 | 6.64 | 8.2 | 0.098 | 3.92 | 10 | 0.15 |

TIE-NANO-CT-161010 | 16 | 10 | 10 | 18.5 | 12.05 | 10.6 | 0.23 | 4.08 | 10 | 0.3 |

TIE-NANO-CT-17116.5 | 17 | 11 | 6.5 | 19.55 | 9.5 | 7.5 | 0.15 | 4.4 | 10 | 0.2 |

TIE-NANO-CT-17.8135 | 17.8 | 13 | 5 | 19.6 | 11.6 | 6.44 | 0.09 | 4.83 | 10 | 0.1 |

TIE-NANO-CT-191405 | 19 | 14 | 5 | 21.3 | 12.5 | 7.05 | 0.098 | 5.18 | 10 | 0.08 |

TIE-NANO-CT-19146.5 | 19 | 14 | 6.5 | 21.25 | 12.7 | 8.5 | 0.127 | 5.18 | 10 | 0.1 |

TIE-NANO-CT-191408 | 19 | 14 | 8 | 22.6 | 12.3 | 10.1 | 0.156 | 5.18 | 10 | 0.12 |

TIE-NANO-CT-191410 | 19 | 14 | 10 | 22.6 | 12.3 | 12.8 | 0.195 | 5.18 | 10 | 0.15 |

TIE-NANO-CT-201208 | 20 | 12 | 8 | 22.0 | 10.2 | 10.55 | 0.25 | 5.02 | 10 | 0.2 |

TIE-NANO-CT-201210 | 20 | 12 | 10 | 22.8 | 10.1 | 12.3 | 0.31 | 5.02 | 10 | 0.25 |

TIE-NANO-CT-201405 | 20 | 14 | 5 | 22.55 | 12.6 | 6.55 | 0.12 | 5.34 | 10 | 0.1 |

TIE-NANO-CT-201410 | 20 | 14 | 10 | 22.55 | 12.6 | 12.46 | 0.24 | 5.34 | 10 | 0.2 |

TIE-NANO-CT-211510 | 21 | 15 | 10 | 23.6 | 13.1 | 12.45 | 0.23 | 5.65 | 10 | 0.2 |

TIE-NANO-CT-211610 | 21 | 16 | 10 | 23.6 | 13.65 | 11.98 | 0.195 | 5.8 | 10 | 0.15 |

TIE-NANO-CT-241810 | 24 | 18 | 10 | 27.0 | 16.1 | 12.5 | 0.234 | 6.59 | 10 | 0.15 |

TIE-NANO-CT-251710 | 25 | 17 | 10 | 27.95 | 15.5 | 12.4 | 0.312 | 6.59 | 10 | 0.15 |

TIE-NANO-CT-25206.5 | 25 | 20 | 6.5 | 27.55 | 18.35 | 9.25 | 0.126 | 7.06 | 10 | 0.1 |

TIE-NANO-CT-252010 | 25 | 20 | 10 | 27.65 | 18.2 | 12.75 | 0.195 | 7.06 | 10 | 0.1 |

TIE-NANO-CT-251910 | 25 | 19 | 10 | 27.75 | 16.2 | 12.7 | 0.234 | 6.91 | 10 | 0.15 |

TIE-NANO-CT-281810 | 28 | 18 | 10 | 29.8 | 17.3 | 12.2 | 0.39 | 7.22 | 10 | 0.2 |

TIE-NANO-CT-281815 | 28 | 18 | 15 | 29.8 | 17.3 | 17.9 | 0.585 | 7.22 | 10 | 0.3 |

TIE-NANO-CT-302008 | 30 | 20 | 8 | 32.8 | 18.2 | 10.0 | 0.312 | 7.85 | 10 | 0.15 |

TIE-NANO-CT-302010 | 30 | 20 | 10 | 33.1 | 18.2 | 13.2 | 0.39 | 7.85 | 10 | 0.2 |

TIE-NANO-CT-302015 | 30 | 20 | 15 | 33.67 | 18.0 | 17.76 | 0.585 | 7.85 | 15 | 0.5 |

TIE-NANO-CT-322015 | 32 | 20 | 15 | 35.0 | 18.0 | 18.3 | 0.702 | 8.16 | 15 | 0.6 |

TIE-NANO-CT-382710 | 38 | 27 | 10 | 40.3 | 25.0 | 12.8 | 0.429 | 10.2 | 15 | 0.25 |

TIE-NANO-CT-443610 | 44 | 36 | 10 | 46.6 | 33.6 | 13.2 | 0.312 | 12.56 | 15 | 0.15 |

TIE-NANO-CT-453015 | 45 | 30 | 15 | 48.3 | 26.4 | 18.2 | 0.88 | 11.8 | 15 | 0.5 |

TIE-NANO-CT-494310 | 49 | 43 | 10 | 51.9 | 42.1 | 13.4 | 0.234 | 14.4 | 20 | 0.12 |

TIE-NANO-CT-504010 | 50 | 40 | 10 | 53.2 | 36.9 | 13.6 | 0.39 | 14.13 | 20 | 0.25 |

TIE-NANO-CT-605010 | 60 | 50 | 10 | 63.8 | 46.5 | 14.1 | 0.39 | 17.27 | 20 | 0.2 |

TIE-NANO-CT-696110 | 69 | 61 | 10 | 72.4 | 57.6 | 14.1 | 0.312 | 20.41 | 30 | 0.2 |

TIE-NANO-CT-867710 | 86 | 77 | 10 | 89.8 | 73.2 | 14.1 | 0.35 | 25.6 | 30 | 0.15 |

TIE-NANO-CT-908210 | 90 | 82 | 10 | 94.5 | 77.4 | 14.1 | 0.312 | 27.0 | 30 | 0.1 |

TIE-NANO-CT-11010010 | 110 | 100 | 10 | 115.0 | 95.2 | 14.5 | 0.39 | 32.97 | 30 | 0.1 |

TIE-NANO-CT-12811315 | 128 | 113 | 15 | 132.6 | 109.5 | 19.5 | 0.88 | 37.8 | 30 | 0.25 |

TIE-NANO-CT-13012015 | 130 | 120 | 15 | 135.4 | 117.0 | 17.5 | 0.585 | 39.25 | 30 | 0.18 |

TIE-NANO-CT-14312815 | 143 | 128 | 15 | 147.5 | 124.2 | 19.3 | 0.87 | 42.55 | 30 | 0.15 |

TIE-NANO-CT-18716715 | 187 | 167 | 15 | 191.5 | 162.5 | 19.38 | 1.17 | 55.57 | 30 | 0.1 |

✅ General-Purpose Current Transformer Cores:

(Compared to precision CT cores)

Designed for current sensing, not precision metering

Used in industrial equipment, UPS, EV chargers, inverters, etc.

Larger dimensions for higher current handling

Accuracy is not critical — focus is on stability and robustness

Suitable for monitoring, protection circuits, and non-billing applications

Lower cost, mechanically robust, and easy to integrate

📌 In short: these cores are built for power electronics and industrial applications where precise ratio accuracy is not essential, but reliability and current capacity are.

Turn your MOBILE horizontally to see the full table

Part Nr. | Core dimension (mm) | Case dimension (mm) | Eff. | Mean | Exciting | Excitation | ||||

od | id | h | OD | ID | H | Ae | Lm | N1=1 | N2=1 | |

TIE-NANO-CT-805030 | 80 | 50 | 30 | 85 | 45 | 35 | 10 | 0.1 | ||

TIE-NANO-CT-906030 | 90 | 60 | 30 | 95 | 55 | 35 | 10 | 0.2 | ||

TIE-NANO-CT-1005030 | 100 | 50 | 30 | 105 | 45 | 35 | 10 | 0.15 | ||

TIE-NANO-CT-1109025 | 110 | 90 | 25 | 115 | 85 | 30 | 10 | 0.3 | ||

TIE-NANO-CT-1158530 | 115 | 85 | 30 | 120 | 80 | 35 | 10 | 0.2 | ||

TIE-NANO-CT-1208030 | 120 | 80 | 30 | 125 | 75 | 35 | 10 | 0.1 | ||

TIE-NANO-CT-1258520 | 125 | 85 | 20 | 130 | 80 | 25 | 10 | 0.08 | ||

TIE-NANO-CT-1259025 | 125 | 90 | 25 | 130 | 85 | 30 | 10 | 0.1 | ||

TIE-NANO-CT-1309030 | 130 | 90 | 30 | 135 | 85 | 35 | 10 | 0.12 | ||

TIE-NANO-CT-13010025 | 130 | 100 | 25 | 135 | 95 | 30 | 10 | 0.15 | ||

TIE-NANO-CT-16013025 | 160 | 130 | 25 | 165 | 125 | 30 | 10 | 0.2 | ||

TIE-NANO-CT-16013050 | 160 | 130 | 50 | 165 | 125 | 60 | 10 | 0.25 | ||

TIE-NANO-CT-18014030 | 180 | 140 | 30 | 185 | 135 | 35 | 10 | 0.1 | ||

TIE-NANO-CT-20015530 | 200 | 155 | 30 | 205 | 150 | 35 | 10 | 0.2 | ||

TIE-NANO-CT-25017040 | 250 | 170 | 40 | 256 | 164 | 46 | 10 | 0.2 | ||

TIE-NANO-CT-27521515 | 275 | 215 | 15 | 280 | 210 | 20 | 10 | 0.15 | ||

TIE-NANO-CT-33022020 | 330 | 220 | 20 | 336 | 214 | 21 | 10 | 0.15 | ||

TIE-NANO-CT-49030515 | 490 | 305 | 15 | 496 | 299 | 21 | 15 | 0.5 | ||

TIE-NANO-CT-52041515 | 520 | 415 | 15 | 526 | 409 | 21 | 15 | 0.6 | ||

TIE-NANO-CT-1165110515 | 1165 | 1105 | 15 | 1175 | 1095 | 25 | 15 | 0.25 | ||

Nanocrystalline Cores for High Frequency Power Transformers

✅ Overview – Nanocrystalline Cores for High Frequency Power Transformers

✔️ High saturation flux density (1.25 T) – enables smaller, more powerful transformers

✔️ Low core loss at 20–50 kHz – improves energy efficiency and thermal performance

✔️ High permeability & low coercivity – reduces magnetizing current and copper loss

✔️ Wide temperature stability – up to 120 °C continuous operation

✔️ Low magnetostriction – quieter operation, minimal audible noise

✔️ Applications:

– High-frequency & high-power SMPS

– Laser, X-ray, and plating power supplies

– Inverter welding machines & IGBT circuits

– Medium/high-frequency induction heating

– Communication & industrial power systems

📌 Compared to ferrite cores, nanocrystalline material offers:

2–5× higher saturation

70–80% lower core loss

10× higher permeability

Better efficiency and thermal behavior

Turn your MOBILE horizontally to see the full table

Case Type:

O – Toroidal core | Ω and Π – Toroidal core with two legs | H – Toroidal core with 4 legs | |

O | Ω | Π | H |

Part Nr. | Core dimension (mm) | Case dimension (mm) | Eff. | Mean | Weight | Power | Case | ||||

od | id | h | OD | ID | H | Ae | Lm | Wt | P | ||

TIE-NANO-HF-503220T | 50 | 32 | 20 | 53.8 | 28.5 | 24 | 1.40 | 12.9 | 131 | 0.5-1 | O |

TIE-NANO-HF-644020T | 64 | 40 | 20 | 68.2 | 37 | 23.5 | 1.87 | 16.3 | 222 | 1-3 | O |

TIE-NANO-HF-805025T | 80 | 50 | 25 | 83.5 | 47.2 | 28.8 | 2.93 | 20.4 | 433 | 3-5 | O |

TIE-NANO-HF-805025S | 80 | 50 | 25 | 83.5 | 47.2 | 28.8 | 2.93 | 20.4 | 433 | 3-5 | Ω |

TIE-NANO-HF-1006020T | 100 | 60 | 20 | 106 | 55 | 25 | 3.12 | 25.1 | 568 | 5-7 | O |

TIE-NANO-HF-1006020S | 100 | 60 | 20 | 106 | 55 | 25 | 3.12 | 25.1 | 568 | 5-7 | Ω |

TIE-NANO-HF-1207020T | 120 | 70 | 20 | 125 | 65 | 26 | 3.90 | 29.8 | 843 | 7-10 | O |

TIE-NANO-HF-1207020S | 120 | 70 | 20 | 125 | 65 | 26 | 3.90 | 29.8 | 843 | 7-10 | Π |

TIE-NANO-HF-1207030T | 120 | 70 | 30 | 125 | 65 | 36 | 5.85 | 29.8 | 1265 | 10-15 | O |

TIE-NANO-HF-1207030S | 120 | 70 | 30 | 125 | 65 | 36 | 5.85 | 29.8 | 1265 | 10-15 | Π |

TIE-NANO-HF-1308040T | 130 | 80 | 40 | 136 | 75 | 46 | 7.80 | 33.0 | 1864 | 15-20 | O |

TIE-NANO-HF-1308040S | 130 | 80 | 40 | 136 | 75 | 46 | 7.80 | 33.0 | 1864 | 15-20 | H |

TIE-NANO-HF-1308050T | 130 | 80 | 50 | 136 | 75 | 56 | 9.75 | 33.0 | 2331 | 20-25 | O |

TIE-NANO-HF-1308050S | 130 | 80 | 50 | 136 | 75 | 56 | 9.75 | 33.0 | 2331 | 20-25 | H |

Amorphous C Cores for Power Inductors and Transformers

✅ Overview – Amorphous C Cores for Power Inductors and Transformers

✔️ High saturation flux density – supports large DC bias without saturation

✔️ Low core loss – lower temperature rise under continuous load

✔️ High permeability – efficient magnetic response even at high frequency

✔️ Compact & efficient – reduced size and copper usage

✔️ Suitable for:

– PFC chokes & filter inductors

– Solar inverter reactors

– High-current reactors & audio transformers

– Medium to high-frequency applications

💡 Compared to traditional silicon steel or ferrite cores, amorphous C-cores offer better magnetic performance, lower loss, and greater thermal stability.

🔧 Custom dimensions available upon request.

Turn your MOBILE horizontally to see the full table

Part Nr. | Core dimension (mm) | Mean | Eff. | Weight | |||||

A | B | C | D | E | F | Lm | Ae | Wt | |

TIE-AM-C-20 | 11 | 13 | 50 | 30 | 35 | 72 | 15.7 | 2.94 | 331 |

TIE-AM-C-32 | 13 | 15 | 56 | 30 | 41 | 82 | 17.9 | 3.47 | 447 |

TIE-AM-C-40 | 13 | 15 | 56 | 35 | 41 | 82 | 17.9 | 4.05 | 522 |

TIE-AM-C-50 | 16 | 20 | 70 | 25 | 52 | 102 | 22.7 | 3.56 | 580 |

TIE-AM-C-63 | 16 | 20 | 70 | 30 | 52 | 102 | 22.7 | 4.27 | 696 |

TIE-AM-C-80 | 16 | 20 | 70 | 40 | 52 | 102 | 22.7 | 5.70 | 928 |

TIE-AM-C-100 | 16 | 20 | 70 | 45 | 52 | 102 | 22.7 | 6.41 | 1043 |

TIE-AM-C-125 | 19 | 25 | 83 | 35 | 63 | 121 | 27.2 | 5.92 | 1157 |

TIE-AM-C-160 | 19 | 25 | 83 | 40 | 63 | 121 | 27.2 | 6.76 | 1322 |

TIE-AM-C-200 | 19 | 25 | 83 | 50 | 63 | 121 | 27.2 | 8.46 | 1653 |

TIE-AM-C-250 | 19 | 25 | 90 | 60 | 63 | 128 | 28.6 | 10.15 | 2085 |

TIE-AM-C-320 | 22 | 35 | 85 | 50 | 79 | 129 | 30.6 | 9.79 | 2148 |

TIE-AM-C-400 | 22 | 35 | 85 | 65 | 79 | 129 | 30.6 | 12.73 | 2793 |

TIE-AM-C-500 | 25 | 40 | 85 | 55 | 90 | 135 | 32.5 | 12.24 | 2856 |

TIE-AM-C-630 | 25 | 40 | 85 | 70 | 90 | 135 | 32.5 | 15.58 | 3635 |

TIE-AM-C-800A | 25 | 40 | 85 | 85 | 90 | 135 | 32.5 | 18.91 | 4414 |

TIE-AM-C-800B | 30 | 40 | 95 | 85 | 100 | 155 | 36.1 | 22.70 | 5879 |

TIE-AM-C-1000 | 33 | 40 | 105 | 85 | 106 | 171 | 39.0 | 24.96 | 6994 |

Nanocrystalline C Cores for High Frequency Applications

✅ Overview – Nanocrystalline C Cores for High Frequency Applications

✔️ Superior to amorphous cores – higher magnetic performance & stability

✔️ Low core loss – efficient at 20–30 kHz switching frequencies

✔️ High saturation induction (1.25 T) – better than ferrites

✔️ Low magnetostriction – quiet operation, reduced noise

✔️ Compact and energy-efficient design

✔️ Applications:

– High-frequency transformers

– Premium audio transformers

– PFC chokes and output inductors

📌 Nanocrystalline C-cores combine high permeability and low losses, making them ideal for demanding magnetic designs under thermal and electrical stress.

✳️ Custom sizes available on request.

Turn your MOBILE horizontally to see the full table

Part Nr. | Core dimension (mm) | Mean | Eff. | Weight | |||||

A | B | C | D | E | F | Lm | Ae | Wt | |

TIE-NANO-C-6.3 | 10 | 11 | 33 | 20 | 31 | 53 | 11.6 | 1.56 | 141 |

TIE-NANO-C-8 | 11 | 13 | 30 | 20 | 35 | 52 | 11.7 | 1.72 | 157 |

TIE-NANO-C-10 | 11 | 13 | 40 | 20 | 35 | 62 | 13.7 | 1.72 | 184 |

TIE-NANO-C-16A | 11 | 13 | 40 | 25 | 35 | 62 | 13.7 | 2.15 | 230 |

TIE-NANO-C-16B | 11 | 13 | 50 | 25 | 35 | 72 | 15.7 | 2.15 | 263 |

TIE-NANO-C-20 | 11 | 13 | 50 | 30 | 35 | 72 | 15.7 | 2.57 | 316 |

TIE-NANO-C-25 | 13 | 15 | 56 | 25 | 41 | 82 | 17.9 | 2.54 | 355 |

TIE-NANO-C-32 | 13 | 15 | 56 | 30 | 41 | 82 | 17.9 | 3.04 | 426 |

TIE-NANO-C-40 | 13 | 15 | 56 | 35 | 41 | 82 | 17.9 | 3.55 | 497 |

TIE-NANO-C-50 | 16 | 20 | 70 | 25 | 52 | 102 | 22.7 | 3.12 | 552 |

TIE-NANO-C-63 | 16 | 20 | 70 | 30 | 52 | 102 | 22.7 | 3.74 | 663 |

TIE-NANO-C-80 | 16 | 20 | 70 | 40 | 52 | 102 | 22.7 | 4.99 | 884 |

TIE-NANO-C-100 | 16 | 20 | 70 | 45 | 52 | 102 | 22.7 | 5.62 | 994 |

TIE-NANO-C-125 | 19 | 25 | 83 | 35 | 63 | 121 | 27.2 | 5.19 | 1102 |

TIE-NANO-C-160 | 19 | 25 | 83 | 40 | 63 | 121 | 27.2 | 5.93 | 1260 |

TIE-NANO-C-200 | 19 | 25 | 83 | 50 | 63 | 121 | 27.2 | 7.41 | 1575 |

TIE-NANO-C-250 | 19 | 25 | 90 | 60 | 63 | 128 | 28.6 | 8.89 | 1987 |

TIE-NANO-C-320 | 22 | 35 | 85 | 50 | 79 | 129 | 30.6 | 8.58 | 2047 |

TIE-NANO-C-400 | 22 | 35 | 85 | 65 | 79 | 129 | 30.6 | 11.15 | 2662 |

TIE-NANO-C-500 | 25 | 40 | 85 | 55 | 90 | 135 | 32.5 | 10.73 | 2722 |

TIE-NANO-C-630 | 25 | 40 | 85 | 70 | 90 | 135 | 32.5 | 13.65 | 3464 |

TIE-NANO-C-800A | 25 | 40 | 85 | 85 | 90 | 135 | 32.5 | 16.58 | 4207 |

TIE-NANO-C-800B | 30 | 40 | 95 | 85 | 100 | 155 | 36.1 | 19.89 | 5602 |

TIE-NANO-C-1000 | 33 | 40 | 105 | 85 | 106 | 171 | 39.0 | 21.88 | 6665 |

Epoxy Coated Nanocrystalline Cores and Bead Cores

✅ Overview – Epoxy Coated Nanocrystalline Cores and Beads

✔️ Small size with excellent magnetic performance

✔️ Epoxy coating allows for custom shapes without mold cost

✔️ Core volume reduction = less copper wire, lower total cost

✔️ High insulation strength – meets 1000V withstand voltage

✔️ High permeability – inductance up to 3× higher than ferrites

✔️ Applications:

– Nanocrystalline bead for surge suppression (e.g. MOSFET)

– IGBT driver transformers

– High-frequency power transformers

– ISDN/network transformers

– EMI/EMC common mode chokes

– Signal transformers (e.g. HD camera systems)

– Precision current transformers

📌 Ideal for engineers seeking compact, cost-effective solutions with high magnetic performance and insulation safety.

🛠 Custom sizes available with short lead time – no tooling required.

Turn your MOBILE horizontally to see the full table

Part Nr. | Core dimension (mm) | Finished dimension (mm) | Eff. | Mean | AL (μH) | ||||

od | id | h | OD | ID | H | Ae | Lm | AL (Min) | |

TIE-NANO-BEAD-040203E | 4 | 2.2 | 3.2 | 4.5 | 1.7 | 3.8 | 0.021 | 0.97 | 10.0 |

TIE-NANO-BEAD-060303E | 6 | 3 | 3.2 | 7.0 | 2.0 | 4.2 | 0.037 | 1.41 | 16.6 |

TIE-NANO-BEAD-060403E | 6 | 4 | 3.2 | 7.0 | 3.0 | 4.2 | 0.025 | 1.57 | 10.0 |

TIE-NANO-BEAD-090503E | 9 | 5 | 3.2 | 10.0 | 4.0 | 4.2 | 0.050 | 2.20 | 15.0 |

TIE-NANO-BEAD-120910E | 11.8 | 8.7 | 10 | 12.8 | 7.7 | 11 | 0.121 | 3.22 | 25.0 |

TIE-NANO-BEAD-140905E | 14 | 9 | 4.5 | 15 | 8 | 5.5 | 0.088 | 3.61 | 16.0 |

TIE-NANO-BEAD-211308E | 21.3 | 13.6 | 8 | 22.3 | 12.6 | 9.0 | 0.240 | 5.48 | 33.0 |

The AL value tolerance of the products is regulated in the quality agreement concluded with the customer.

Nanocrystalline Cores for Magnetic Amplifiers for Switched Mode Power Supplies

✅ Overview – Nanocrystalline Cores for Magnetic Amplifiers (Mag-Amp)

✔️ Specially heat-treated with longitudinal magnetic field for optimized switching behavior

✔️ High saturation flux density (1.25 T) – compact design with fewer coil turns

✔️ High rectangle ratio (Br/Bm ≥ 94%) – ensures low dead-angle voltage under high current

✔️ Low coercivity (Hc ≤ 36 A/m) – fast reset capability, excellent efficiency

✔️ High Curie temperature – stable performance at elevated operating temps

✔️ Applications:

– Switched-mode power supplies (SMPS)

– Desktop and server power units

– Magnetic amplifiers for voltage regulation

📌 Available in compact sizes optimized for secondary-side regulation in SMPS systems.

Optional: Co-based amorphous material for even lower coercivity and loss – ideal for high-end power supplies.

🛠 Custom designs available on request.

Turn your MOBILE horizontally to see the full table

Part Nr. | Core dimension (mm) | Finished dimension (mm) | Eff. | Mean | Saturation | ||||

od | id | h | OD | ID | H | Ae | Lm | 2Φm | |

TIE-CORE-MAG-AMP-100705Z | 10 | 7 | 4.5 | 12 | 5 | 6.8 | 0.053 | 2.67 | 12.4 |

TIE-CORE-MAG-AMP-120803Z | 12 | 8.4 | 3.2 | 14.7 | 5.9 | 5.4 | 0.045 | 3.20 | 10.6 |

TIE-CORE-MAG-AMP-120804Z | 11.8 | 8.7 | 4.2 | 13.9 | 6.8 | 6.0 | 0.051 | 3.22 | 11.9 |

TIE-CORE-MAG-AMP-120805Z | 12 | 8 | 4.5 | 14.7 | 6.2 | 6.8 | 0.070 | 3.14 | 16.5 |

TIE-CORE-MAG-AMP-151005Z | 15 | 10 | 4.5 | 17 | 8 | 7.1 | 0.088 | 3.93 | 20.6 |

TIE-CORE-MAG-AMP-191505Z | 19 | 15 | 5 | 21 | 13 | 6.6 | 0.078 | 5.34 | 18.3 |

Amorphous and Nanocrystalline Gap Cores

✅ Overview – Amorphous and Nanocrystalline Gap Cores

✔️ High saturation flux density – excellent DC bias performance, avoids saturation

✔️ Gap structure – enables stable operation under large current loads

✔️ Low core loss – improves efficiency and reduces temperature rise

✔️ High permeability – effective inductance with fewer turns

✔️ Gap size customizable – tailored to meet required AL and inductance values

✔️ Applications:

– PFC chokes

– Output filter inductors

– Solar inverter inductors

– Hall effect transducers

📌 Gap cores are optimized for power electronics where precise inductance and current handling are critical. Both amorphous and nanocrystalline materials available.

🛠 Custom gap sizes and dimensions can be manufactured to meet your application needs.

Turn your MOBILE horizontally to see the full table

Part Nr. | Core dimension (mm) | Finished dimension (mm) | Eff. | Mean | Gap | AL | ||||

od | id | h | OD | ID | H | Ae | Lm | Lg | AL | |

TIE-GAP-CORE-201208 | 20 | 12 | 8 | 21.7 | 10.8 | 9.9 | 0.28 | 5.0 | 0.5 | 0.125 |

TIE-GAP-CORE-261610 | 26 | 16 | 10 | 28.3 | 14.0 | 12.8 | 0.44 | 6.6 | 0.5 | 0.165 |

TIE-GAP-CORE-402515 | 40 | 25 | 15 | 44.4 | 22.0 | 18.8 | 0.99 | 10.2 | 0.8 | 0.240 |

TIE-GAP-CORE-603525 | 60 | 35 | 25 | 64.0 | 31.0 | 29.0 | 2.75 | 14.9 | 5.0 | 0.148 |

The AL value tolerance of the products is regulated in the quality agreement concluded with the customer.